HDI Series

5HP to 15HP Duplex

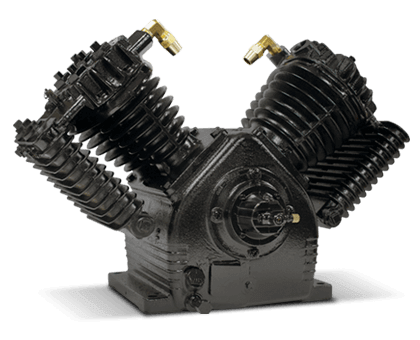

Pressure-Lubricated, Cast-Iron Construction with Slow RPM

The Air-Cooled, Pressure-Lubricated, Reciprocating HDI Series Duplex – 5 to 15 HP is Engineered to Provide a Heavy-Duty, Durable and Dependable Air Compressor Built to Withstand the Most Demanding Industrial Environments.

Duplex Units are equipped with 2-Stage, 2-Cylinder (247) or 4-Cylinder (447) Cast-Iron Compressor Pumps, 2 ODP motors, and 2 optional Magnetic Starters with an Alternator Relay, or an optional Alternating Control Panel (ACP) providing Reliable, Continuous-Use, 24/7 Operation.

The Heavily Weighted Cast Iron Pumps and Low RPM enhance heat dissipation and enable up to a 75-80% duty cycle. DV’s proprietary pressure lubrication process ensures oil is delivered to journal bearings and all necessary components, minimizing oil carry-over and friction.

The moving components of these pumps are machined, honed, balanced and assembled in Canada. Rugged construction and long life allows DV Systems to confidently offer an unprecedented 7 Year Warranty for the HDI DV15-HDI-Series.

Highlights

- Rugged & Reliable

Ideal for Demanding Industrial Environments - Heavily-Weighted, Cast-Iron Pumps

Provides 75-80% Duty-Cycle Operation - Slow Compressor Pump RPM

Long-Lasting Operation - Deep-Finned Cast-Iron Inter-Cooler

Enhances Heat Dissipation - 7 Year Limited Warranty

Rugged Construction & Long Life

Download the DV Systems HDI Series Duplex 5HP to 15HP Brochure (PDF)

Available Models

| Model | HP | Tank | SCFM @ 150 PSI | Pump | Pump RPM | Height | Width | Depth | Weight (lbs) |

|---|---|---|---|---|---|---|---|---|---|

| TAP-5562 | 5 | 120 Horiz. | 2 x 19.8 | 2 x 247 | 635 | 54 3/4″ | 81 1/2″ | 26 1/2″ | 1073 |

| TAS-5562 | 7.5 | 120 Horiz. | 2 x 25.9 | 2 x 247 | 800 | 54 3/4″ | 81 1/2″ | 26 1/2″ | 1103 |

| VAT-5583 | 10 | 240 Horiz. | 2 x 36.8 | 2 x 447 | 590 | 62 1/2″ | 107 3/4″ | 30 3/4″ | 1940 |

| VAV-5582 | 15 | 240 Horiz. | 2 x 52.1 | 2 x 447 | 880 | 62 1/2″ | 107 3/4″ | 30 3/4″ | 2074 |

XL Duplex – Full Featured Package

The XL Duplex Package Features Cast-Iron Compressor Pumps, ODP Industrial Electric Motors, Definite Purpose Magnetic Starters & Relay, Low-Oil Shutdown Monitors, an Auto Drain, and an Air Receiver.

x 2 Cast-Iron Pumps

- Cast-Iron Cylinder Head, Cylinders, Pistons

- Machined, Carbon-Steel Disc Valve Assemblies

- Carbon Steel Connecting Rods with Bearing Inserts

- Deep-Finned Cast-Iron Intercooler

x 2 ODP Motors

- High Efficiency Open Drip Proof Electric Motors

- North American Made

x 1 Air Receiver

- 120 or 240 Gallon Horizontal Tanks

- 1-1/4″ NPT Ball Valve, Pressure Switch, Safety Valve & Pressure Guage.

- ASME Approved & CRN Registered

+ XL Components

- Magnetic Starters (x2) + Alternator Relay

- Low Oil Level Sight / Shut-Down Monitor (x2)

- Auto Drain (Electronic Timer / Electronic Zero Loss / Pneumatic)

MS Duplex – Magnetic Starter & Relay Package

The MS Duplex Package Features Cast-Iron Compressor Pumps, ODP Industrial Electric Motors, Definite Purpose Magnetic Starters & Relay, and an Air Receiver. The Magnetic Starters & Relay act as a Simple Alternator, Enabling each Pump & Motor Combination to Start Alternately.

x 2 Cast-Iron Pumps

- Cast-Iron Cylinder Head, Cylinders, Pistons

- Machined, Carbon-Steel Disc Valve Assemblies

- Carbon Steel Connecting Rods with Bearing Inserts

- Deep-Finned Cast-Iron Intercooler

x 2 ODP Motors

- High Efficiency Open Drip Proof Electric Motors

- North American Made

x 1 Air Receiver

- 120 or 240 Gallon Horizontal Tanks

- 1-1/4″ NPT Ball Valve, Pressure Switch, Safety Valve & Pressure Guage.

- ASME Approved & CRN Registered

+ MS Components

- Magnetic Starters (x2) + Alternator Relay

Basic Duplex + Options

Standard HDI Series Duplex Units are factory equipped with the following Components.

x 2 Cast-Iron Pumps

- Cast-Iron Cylinder Head, Cylinders, Pistons

- Machined, Carbon-Steel Disc Valve Asssemblies

- Carbon Steel Connecting Rods with Bearing Inserts

- Deep-Finned Cast-Iron Intercooler

x 2 ODP Motors

- High Efficiency Open Drip Proof Electric Motors

- North American Made

x 1 Air Receiver

- 120 or 240 Gallon Horizontal Tanks

- 1-1/4″ NPT Ball Valve, Pressure Switch, Safety Valve & Pressure Guage.

- ASME Approved & CRN Registered

+ Plus Additional Options:

INDIVIDUAL ITEMS

- Low Oil Level Sight / Shut-Down Monitor (x2)

- Auto Drain (Electronic Timer / Electronic Zero Loss / Pneumatic)

MS PACKAGE

- Magnetic Starters (x2) + Alternator Relay

XL PACKAGE

- Magnetic Starters (x2) + Alternator Relay

- Low Oil Level Sight / Shut-Down Monitor (x2)

- Auto Drain (Electronic Timer / Electronic Zero Loss / Pneumatic)

ACP PACKAGE

- Alternating Control Panel (ACP)

- + More (See Configuration 1 Below)

Overview 247 / 447 Compressor Pumps

The Two Stage, Two Cylinder 247 & Two Stage, Four Cylinder 447 Compressor Pumps Feature Cast-Iron Construction & Slow RPM, Making Them Ideal for Demanding Industrial Environments.

Precision-Machined, Honed, Manufactured & Assembled in Canada.

7 Year Limited Warranty

Solid, Cast-Iron Cylinders

- Minimizes Distortion from Assembly Torque & Heat.

- Precision-Machined Cylinder Walls Honed to reduce Friction & minimize Oil Carry-Over & Friction.

- Extra deep fins provide increased cooling & strength.

Balanced Pistons

- Heat-Treated & Stress-Relieved Connecting Rods Cast from Ductile Iron & Assembled with Babbit Bearings Increase Durability & Reduce Wear on the Crankshaft.

- High-Pressure, Cast-Iron Pistons withstand extreme forces. Low-Pressure Pistons made from aluminum alloy.

- Extra wide compression rings designed to work seamlessly with the oil control rings & scraper.

Balanced Crankshaft

- Ensures smooth, extended-life operation.

- Precision-ground journals furnished with inserts for long, trouble-free operation.

- Tapered shaft for reliable & effective transmission.

Balanced Flywheel

- Airfoil-type spokes provide continuous, cooling air flow.

- Smooth, Vibrationless Operation.

Quiet, Quick Acting Valves

- Machined, carbon-steel valves balance air passages & structural integrity.

- Hardened carbon steel valve guides & stainless steel disc valves and springs

- Individually tested & easily serviced.

Cool Cylinder Head

- Quick Cooling, Deep, Directional Fins.

- Fast, efficient flow of cooler intake air due to compact, streamlined air passages in the cylinder head.

Load Free Starting

- 10 HP & 15 HP Equipped with centrifugal pressure release (CPR) allowing the motor to start before a pressure load is applied to the pump.

Short Stroke Design

- Large bore, short-stroke & slow operating speeds improves life expectancy & provides high air delivery.

Air Receivers

- CRN & ASME Approved.

- Maximum working pressure: 200 PSI

- Complete with pressure gauge & CRN & ASME Approved safety valve.

Manifold Assembly

- Two Pressure Switches

Factory Pre-Set to Operate at 115/150 PSI (792.9/1034.kPa) Cut-In/Cut-Out - Maximum Operating Pressure

Adjustable to 175 PSI (1206.6 kPa)

Ball Bearings

- Oversized, Heavy load capacity ball bearings ensures a free-running crankshaft.

- Lubricated from the crankcase, requiring no maintenance.

Deep-Finnned Cast-Iron Intercooler

- Enhances heat dissipation between compression stages.